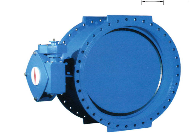

Fire Safe - Butterfly High Performance Valves

Model: #H401ST

Specification

Applications

UTD valves handle a wide range of conditions and media such as corrosive chemicals, water, gases (Oxygen, Nitrogen…), acids, alkalis, hydrocarbons plus many other fluids, with seat PTFE, HPTFE, TFM, VITON, METAL…. UTD’s standard valve line has been specifically designed to meet most applications. When applications demand special requirements, UTD offers valves and materials that meet these needs.

Product Detail

Applications

UTD valves handle a wide range of conditions and media such as corrosive chemicals, water, gases (Oxygen, Nitrogen…), acids, alkalis, hydrocarbons plus many other fluids, with seat PTFE, HPTFE, TFM, VITON, METAL…. UTD’s standard valve line has been specifically designed to meet most applications. When applications demand special requirements, UTD offers valves and materials that meet these needs.

Fire Safe

UTD’s Butterfly High Performance Valves are available with proven bi-directional fire safe seats on:

Wafer, Lug and Double Flange bodies:

ASME Class 150 2-40"(50-1000mm)

ASME Class 300 2-24"(50-600mm)

ASME Class 600 2-20"(50-500mm)

For reliable control of flammable and hazardous fluids in petroleum, petrochemical, chemical and other high-risk applications, the fire safe DESIGN combines superior performance, extended service life and compliance with the most demanding worldwide fire-test standards – before, during and after a fire!

In normal service, the Fire Safe combination resilient/metal seat seals zero-leakage in both directions of line media flow through the full rated pressure and temperature ranges. When closed, the disc remains compressed against the resilient mechanically loaded seat, which is securely locked in place by a full-faced retainer. Line media pressure strengthens the seal.

In the event of a fire, if excessive heat destroys the resilient seat materials, either partially or completely, the seat provides a constant metal–to–metal backup seal.

In actual fire conditions, line pressure is immediately reduced and the entire area is hosed down. The resulting pressure drop and rapid cool down causes many valves to fail. The Fire Safe design does not rely on line media pressure to seal, therefore the valve offers superior low pressure performance to competitive designs. The Inconel® metal seat functions as a spring mechanism, which allows for expansion and contraction without breaking contact with the disc. Additionally, the Inconel seat offers better corrosion and heat resistance and greater strength than the stainless steel seats commonly used.

The UTD Butterfly High Performance Valves perdelivers proven fire safe protection not only in the lab, but also where it counts the most – in the field.

Fire Safe Seat Operation

The seat assembly in normal service contacts the disc with both the resilient seat and metal seat. During and after a fire, when the resilient seat has been partially or completely destroyed, the metal seat provides a positive seal by remaining in constant contact with the disc in either direction of media flow.